Parking structures look patient from the road, yet they are frequently the absolute most stressed out concrete on an industrial internet site. They take vibration coming from visitor traffic, seasonal temp swings, chlorides from deicing sodiums, as well as steady real-time bunches that sneak in to the groundwork. When motion begins to show up as cracks, misaligned junctions, or stooping maintaining walls, the treatment rarely remains at the area. For lots of managers, the absolute most reputable path to maintain as well as extend the life of a garage is a targeted system of deep foundation repair making use of helical piles, micropiles, protection piles, as well as helical tieback anchors.

I have actually spent sufficient evenings in active garages to understand the job can easily certainly not shut down earnings any kind of longer than essential. Equipment needs to remove reduced space, punching spoils have to be actually regulated, and also workers should collaborate along with surveillance as well as traffic control. The services listed below are actually not academic. They are what in fact matches under a six-foot-eight allowance indicator and maintains a garage secure while the solution happens.

Why auto parking constructs relocate the initial place

Movement comes from a handful of acquainted offenders. Urban garages typically remain on changeable filler where aged cellars were backfilled along with debris and also soft soils. As time go on, this component consolidates under tons, and columns settle erratically. Boundary keeping wall surfaces bow when drainage gets blocked out as well as ground stress climbs. In seaside areas and locations that observe hefty salting, reinforcement corrodes, cement fractures, as well as Helpful hints bunch paths shift to members that were never planned to bring them. On sloped websites, side creep in clay-based may push piles and grade beams off line. Seismic events do their part as well, loosening up backfill as well as opening joints.

The telltales are consistent: hairline splits that widen seasonally, development joint voids that no more close, cavalcades that present an action in the bottom layer grout line, deck inclines that have to be shimmed at the empties, and also shear cracks near wall structure corners. I have actually determined row resolution of 3/4 inch at one bay as well as virtually 2 ins three gulfs over, all within a design that looked flawlessly straight coming from the street. That sort of differential is actually hard on post-tensioned decks as well as turns up as consistent basement waterproofing failures unless the groundwork is actually stabilized.

Where helical systems as well as micropiles fit

Deep base repair for business garages commonly fixates four devices: the helical pile, the resistance pile, the micropile, and the helical tieback anchor. Each has its sweet spot.

Helical stacks are screwed right into the soil with a torque-monitored electric motor and a square or round shaft. They excel in clay-based, filler, as well as heterogeneous stratigraphy where displacement proves out as well as torque relationship offers trustworthy capability directly. I like them under internal columns in reduced clearance locations because setup requires very little spoils as well as may be organized in between parked autos. Commercial helical pile installation often pairs with brand new brackets bonded or ran off to existing pile limits to grab load without full excavation.

Resistance heaps, at times called press piers, count on mounting sections of steel water pipes right into the ground using the superstructure as response. They suit situations where upright loads are higher, overhanging space is restricted, and base or even a thick stratum exists within a sensible reach. Commercial resistance pile installation is common when deriving a particular pillar that is currently lugging body weight, considering that the jacking method makes good use of that mass.

Micropiles are small-diameter pierced as well as grouted heaps with either threaded bar or case as encouragement. They radiate where get access to is tough but bunch demands are actually considerable, or even where impediments will create helical installment uncertain. Micropile installation handles adjustable grounds, rocks, and quite strong coatings, and also along with effective connect spans these factors carry high tons in each pressure as well as compression. Commercial micro pile installation, frequently meant micropiles in standards, is my go-to under massive ramp pillars or even seismic retrofits where ductility matters.

Helical tieback anchors are actually for side restriction. Set up through turning right into retained soil coming from the within skin of a wall surface, they establish pressure through coils installed in qualified dirt. A plate or even waler distributes the tons along the wall structure. Commercial helical tieback anchor installation can easily straighten out a stooping garage wall surface as well as maintain it there certainly, along with urgent proof by torque as well as bunch screening as needed.

Diagnosing the problem prior to opting for a tool

Rushing to a repair without a tight diagnosis invites callbacks. The first order of business is actually to equipment the framework. Straightforward crack determines that report seasonal movement support separate thermal habits coming from structure drift. A level survey throughout the deck shows whether negotiation is even or localized. In one downtown garage we discovered an 1 ⅛ inch plunge within a 24-foot bay that associated with an old utility trench under the slab. The rest of the grid was stable. Mounting wads under every cavalcade would certainly have squandered cash; two piles under the afflicted line along with a moderate lift solved the practical problem.

Subsurface exploration matters too. A few hand augers at the boundary hardly inform the complete story. For deep foundation repair, I prefer borings that brace the neglecting places as well as affect to rejection or at the very least 30 to fifty feets, depending upon local geography. Where drainage problems are felt, cam operate in under-slab lines and also weep bodies purchases itself. If salts have affected the deck, have centers checked for chlorides at rebar intensity; that records forms the series for structure work versus deck remediation.

Once we know what is moving and also why, the selection amongst helical piles, protection piles, micropiles, and helical tiebacks penetrates. High axial lots with tough grounds and low clearance aspect toward micropiles. Modest lots with layered stuffing as well as clays lean toward helical piles. Brief scope to a difficult bearing coating and also a sizable superstructure benefit resistance piles. Inclined wall structures with limited excavation room require tieback anchors.

Planning the function in an active garage

Logistics may overwhelm specialized style otherwise managed early. Headroom restrictions most rigs. For helical and also tieback work, I indicate power or gas drive scalps mounted on sleek companies and even skid-steer attachments that clear seven feet. For micropiles, low-clearance drill rigs along with fractional poles always keep spoil as well as clutter workable. Exhaust squeeze or even electrical energy is actually excellent in encased garages; typically, air premium surveillance is a must.

Noise and also vibration factors to consider are non-negotiable for hospitals, lodgings, as well as home high rises along with shared car parking. Helical and micropile techniques are normally low vibration. Resistance heaps involve mounting, which is quiet, yet demolition for brackets may make a noise. Plan loud help off-peak hrs and also team up along with management properly ahead of time so tenants aren't surprised.

Traffic management is actually a safety and security thing and a routine item. Functioning a row pipe typically indicates shutting out pair of neighboring stalls. On a 600-stall garage, taking 12 to 18 delays inactive each time spreads out the ache but keeps profit. The phasing strategy ought to draw up each gulf, each core exercise, each grout mix set, and each assessment. A good superintendent will definitely keep daily standups along with operations to verify get access to and also egress options, signs, and also escorts if streets should be shared by the public.

Helical stacks under columns: a sensible sequence

Underpinning an indoor pillar along with helical piles starts along with subjecting the ground. In numerous garages, the column rests on a grade beam along with buttocks. Sawcut only good enough slab to access the shaft edge, safeguard cable televisions if the deck is actually post-tensioned, and bank the column if airlift is actually organized. A pre-engineered steel bracket is actually connected to the ground or even beam, then the helical pile is advanced via an aviator opening next to the structure in to the soil.

Torque is actually the feedback mechanism. A traditional commercial helical pile installation will target twist in the variety that correlates to the needed bunch along with a safety aspect, for instance 6 to 8 kip-ft for a 40-kip tasks at hand, depending upon the body's torque-to-capacity proportion. I prefer to observe a minimum embedment deepness that engages a minimum of 2 coil layers in the bearing stratum. As soon as at depth, the heap is actually reduced to altitude, a hat is actually attached, as well as the brace transfers lots. If lift is intended, gas jacks between bracket as well as skyscraper bring the factor back towards design altitude. Lifts are commonly confined to 1/4 inch per celebration to protect finishes as well as connections.

Helical heaps carry velocity. 2 to 4 piles each day per crew is realistic in reduced space along with low surprises. Spoils are imperceptible, and along with correct floor coverings as well as housekeeping, our team can resume travel streets each night.

Resistance stacks when the structure may do the work

Resistance heaps shine when there is a quick road to refusal and the property's dead lots is considerable. The method utilizes that tons to jack steel pipe portions downward up until they bear on dense material or even till gas tension shows capacity. In a garage, that usually pairs with a small brace bolted or even joined to the ground. The functional restricting variable is just how much power the bracket as well as concrete can easily take without local area squashing, so a mindful consider cement strength as well as reinforcement is actually required.

I have used resistance piles to really good result on a 1980s garage that picked one edge where filler decreased over clay. The jacking tensions connected with the target in three to five portions, as well as our experts had the capacity to elevate the resolved bay by nearly an in. The superintendent set up the jack-downs throughout first blush hours when the garage was vacant enough to offer a crystal clear safety border. Because the method produces no drilling spoils, the clean-up was very little. The caveat: if base is actually deep-seated or even the soils carry out certainly not densify under mounting, this body may operate long on sectors as well as cost.

Micropiles for massive lifts as well as complicated soils

Micropiles are actually the utility vehicle when the tons are actually high and also the dirts are stubborn. The rotary tool reduces a small-diameter hole, commonly 5 to 9 inches, via whatever exists beneath: cobbles, outdated groundworks, thick tills. The workers puts encouragement, often a high-strength threaded bar or at times a cased body, after that injects grout to connection the pile to the bordering ground. Load moves with skin layer abrasion and also, if inspected to rock, with edge bearing.

Micropiles carry impressive bunches in a small footprint. A solitary micropile can bring 100 kips in compression in a lot of environments, and along with bonded spans readjusted, tens of kips in strain. They likewise behave properly under seismic loads. In a medical center garage retrofit, our company used varieties of micropiles to generate new stack caps under ramp columns with no effect to client car park past the urgent work region. Grout handling is the distinction here: maintain a clean distribution pathway, temperature-control the mix in winter, and log cement takes very carefully so you understand when the ground is accepting more than developed, which might point to gaps that require to become addressed.

Because micropiles are punched, spoils monitoring issues, specifically in below-grade levels with no easy departure. Suction units, spill racks, and also a self-displined hose layout keep the wreck inside the work zone. Sound is more than with helical installations, yet along with contemporary rigs as well as mufflers, our team have satisfied strict medical center limits.

Stabilizing and aligning walls along with helical tieback anchors

Parking frameworks commonly consist of free-standing or even partially retained wall surfaces along the border. In time, inadequate drain or even surcharge coming from surrounding websites presses these walls inner. Tieback anchors counter that stress. Helical tieback anchors put up coming from the inside skin via cored openings or even wallets in the wall structure, then advancement right into the retained soil till the coils arrive at an untroubled zone. The anchor pole hooks up to a bearing layer or even waler inside the garage, and also the assembly is prestressed to a pointed out load.

The elegance of helical tiebacks is quick capacity verification. Installment twist correlates to disengagement protection, and also our team can verification exam supports as our team go. On a downtown garage along with a 12-foot retained height, our team spaced tiebacks at 6 feet flat and 4 feet vertically, each with a design load of twenty kips. The setup team worked bay by bay, coring with the wall structure, putting in the anchor along with a right-angle ride scalp, and installing plates that fit within the bumper area. The wall moved back about ⅜ in at the most awful sites in the course of prestressing, then stabilized. Leak gaps were actually restored and drainage matting put in on the outdoor during a different stage, which is vital if you yearn for the anchors to take pleasure in a long, peaceful life.

Tiebacks are certainly not a magic bullet. If the wall structure has lost considerable section as a result of oxidation or even spalling, you should mend the concrete and encouragement, or incorporate a waler unit that rearranges tons. In seismic areas, mix tiebacks along with pliable specifying and also check for hammering versus adjoining structures.

Brackets, relationships, and also what actually holds the load

Underpinning is only as strong as its hookups. I spend as much time on brackets as well as walers as on the heaps on their own. For helical and also resistance pile braces, validate the bearing region on concrete and also include supplementary enhancing if analysis reveals localized tensions beyond the concrete's ability. In more mature garages with lower-strength concrete, it prevails to sew practice and also epoxy dowels to make arrest. If assembly is involved, qualify treatments as well as shield ligaments and also bars from heat.

For tiebacks, the plate and also nut are actually the apparent components, yet the load pathway often goes through a waler that disperses the anchor power along the wall structure. An effectively developed waler decreases tension attentions and always keeps the wall structure from splitting around support factors. Galvanization or even epoxy finishing on left open steel expands service life in threatening environments.

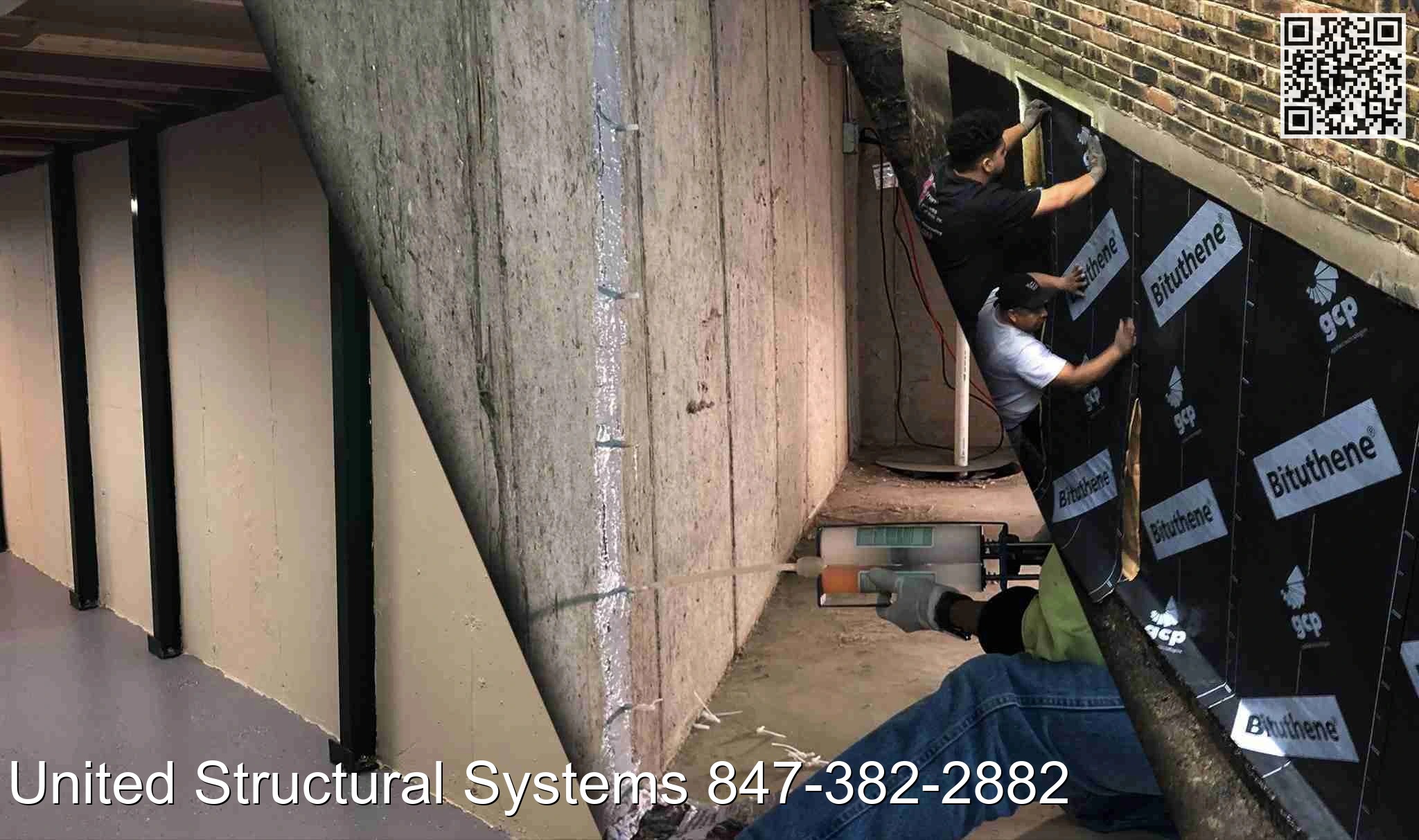

Integrating structure deal with foundation crack repair and also waterproofing

Repair plans rarely stop at the structure. The moment movement is prevented, the cracks remain. Foundation crack repair in garages must represent chlorides and also continuous direct exposure to humidity. I choose a two-step method: shoot structural cracks with low-viscosity epoxy where structural constancy concerns, at that point use polyurethane shot for definitely leaking fractures. Surface sealers as well as traffic-bearing membranes maintain chlorides out. If the settlement deal caused ponding at empties, recast the drainpipe altitudes or include local topping, however do not do this till after founding has taken the slab back to its long-lasting position.

In instances where corrosion is advanced, galvanic anodes installed around repaired regions slow future harm. Correlative the surface area work very carefully with stack head and also brace locations to avoid potential disputes when evaluating or even adjusting hardware.

Verifying functionality: testing and monitoring

Proof screening is actually the basis of self-confidence. For helical piles, twist logs are typical, however I still specify occasional compression bunch exams, especially for the first of each key in a project, to calibrate torque-to-capacity correlations. For resistance stacks, mounting pressures are actually indicated, and also lifts are actually measured at the column center as well as nearby management aspects. Micropiles and tiebacks receive evidence or functionality exams per the style, with hold time periods and creep standards documented.

Post-construction, an easy monitoring program pays dividends. Questionnaire monoliths at pick columns as well as wall structure factors, read quarterly for the first year, catch any sort of residual action. If the garage is actually matched to a property with sensitive cladding, portion records with the front crew. On one mixed-use project, this partnership stopped a second round of repair services through recording a minor design as a result of a leaking drainpipe that our team repaired just before it led to trouble.

Budget, timetable, and also the reality of phasing

Owners talk to pair of inquiries initially: how much and how long. A candid selection aids. Helical piles under internal columns in a traditional city garage typically land in the mid four bodies per heap set up, depending on intensity, bracket complexity, and also accessibility. Micropiles set you back additional every aspect, yet one micropile may replace pair of or even three helicals in high-load situations, focusing the overall. Tieback anchors, along with coring, plates, as well as testing, land similarly to helical pile systems. Protection stacks differ with depth to refusal; if refusal is actually shallow, they are actually affordable, however long terms add quickly.

Schedules are actually extra predictable than they used to be. A team may put in 3 to 8 helical piles per day under active conditions, pair of to 4 micropiles along with screening, and also 6 to 10 helical tiebacks, supposing accessibility is very clear as well as no unforeseen blockages. Include time for leveling, bracket manufacture, and cement repair. Phasing to always keep the garage open typically stretches the calendar however not the work amount. Evening job sets you back even more per hr yet can easily squeeze the period if the garage can be given over totally to the crew during the course of those windows.

Safety and code factors to consider certain to garages

Garages hold special threats: carbon monoxide gas, reduced visibility, cramping spins, as well as untrained passerbies. Security plannings consist of air tracking, extra lighting fixtures, obstacles that in fact cease cars and trucks, and also lookouts whenever rigs are moved. Fire security systems in garages, including standpipes and sprinklers, need to continue to be crystal clear as well as energetic. Numerous legal systems demand permits for structural foundation repair and rich structure elements, as well as special assessments for micropiles and also tiebacks. Correlative very early along with the authorization possessing jurisdiction. Examiners appreciate well-maintained delegations that present the stack or even support layout, screening protocols, as well as the strategy to safeguard the existing structure.

When to pick which system

Choosing one of helical piles, protection stacks, micropiles, and helical tieback anchors is actually certainly not a company commitment decision. It is a dirt, tons, as well as strategies choice. If you require each squeezing as well as strain capability along with low vibration and also restricted spoils, helical piles and also helical anchors are powerful. If you have a massive structure as well as a superficial dense level, protection stacks may supply capacity rapidly along with marginal tools. If you face boulders, profound rejection, or high loads that require a ductile, evaluated element, micropiles carry the day. Many garages that have resided a handful of decades take advantage of a mix: helical piles under light pillars, micropiles under ramps and also primaries, and also tieback anchors on wall structures that pitch. That strategy respects both the design as well as your business reality of keeping stalls available.

A quick field story

A coastal metropolitan garage, 5 levels with retail at grade, began presenting water leaks and also a drift in a back corner. Survey data verified almost 1.5 ins of negotiation at 2 interior pillars and a head of about 3/4 inch in the adjacent keeping wall surface. Borings showed 10 to 14 feet of mixed stuffing over loosened sand, along with heavy sand at 18 to 22 feet. Chloride examinations at the deck warned high amounts in the top floor covering near the ramps.

We phased the repair over six full weeks without closing the garage. Micropiles moved under the 2 massive ramp columns: four every pillar, pierced to 25 feet with a 10-foot bonded span, evidence assessed to 125 kips. Helical piles got two lighter columns along with an intended capability of 40 kips each, driven to torque at around twenty to 22 feets. The wall obtained helical tieback anchors at two altitudes, proof evaluated to 25 kips. Our company lifted the resolved bay in 3 increases of ⅜ inch each, seeing the growth joints as well as post-tensioning anchors like war hawks. Seep fixings adhered to along with polyurethane treatment and a brand new visitor traffic finish in the most awful lanes. After one year of surveillance, motion continued to be within 1/16 in, and also the wall had its own line. The proprietor stated far fewer ponding complaints and better resident contentment in the stores below.

The job of experience and judgment

Specifications as well as data slabs illustrate helical piles, protection piles, micropiles, and tieback anchors in tidy terms. Area job is actually not constantly well-maintained. You struck an old ground, torque dives prematurely, or cement takes double the counted on amount. That is when adventure matters. In some cases the appropriate relocation is actually to move a heap 12 inches to get rid of a buried beam, incorporate a helix layer to go after capacity a little bit of much deeper, or even switch a planned helical to a micropile in a discrete location considering that the ground is not behaving. Commercial foundation repair, adequately done, is a set of tiny correct choices supported by good design and also honest reporting.

Owners and location supervisors do certainly not require to become geotechnical specialists, but they should demand a service provider who can discuss the lots course in plain terms, present the amounts that sustain ability, as well as supply a tracking plan. When those parts remain in location, commercial foundation stabilization stops being unexplainable as well as ends up being an expected, convenient servicing investment.

A concise manager's guidelines for structure stablizing in garages

- Confirm the trouble along with unbiased information: study, crack mapping, as well as at the very least pair of borings near the influenced area. Match the device to the need: helical piles as well as helical anchors for speed and low vibration, protection heaps for superficial rejection along with hefty responses, micropiles for higher bunches and also complicated soils, tieback anchors for sidewise restraint. Demand testable functionality: torque logs, bunch exams, and crystal clear recognition criteria. Plan for procedures: phasing, stall closures, sky quality, and also sound home windows acknowledged in advance. Close the loophole: do with foundation crack repair, drain fixes, as well as a short-term surveillance plan.

Looking ahead

Parking properties can easily last far beyond their initial style daily life if their groundworks are actually maintained truthful as well as their water drainage is actually maintained. Helical piles, protection stacks, micropiles, as well as helical tieback anchors offer us resources to correct resolution as well as sidewise action without transforming the building right into a jobsite for months. Applied with care, they lessen disruption, safeguard income, as well as come back a property to the peaceful, boring service that a garage ought to supply. The profession depends on deciding on the right factor for each and every site, mounting it with discipline, and also verifying its functionality prior to moving to Commercial Helical Pile Installation the next bay.